How to Maintain Electric Motors for Long-Lasting Performance

Electric motors power everything from industrial machinery to home appliances. But like any machine, they need proper care to ensure longevity and efficiency. Neglecting maintenance can lead to breakdowns, costly repairs, and reduced performance. So, how can you keep your electric motor in top shape? Let’s dive into the best maintenance practices!

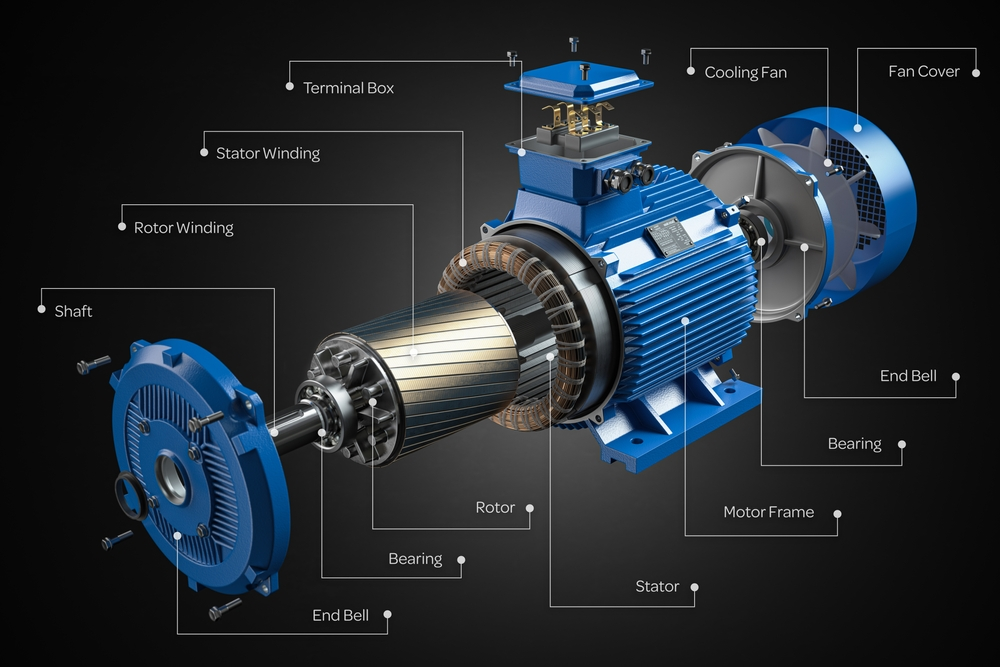

Understanding Electric Motors

Electric motors convert electrical energy into mechanical motion. They come in various types, such as AC and DC motors, each designed for specific applications. Understanding their functionality helps in maintaining them effectively.

Why Maintenance is Essential

Regular maintenance prevents sudden failures, extends lifespan, and improves efficiency. It also reduces operational costs and ensures safety in industrial and household applications.

Types of Electric Motors

- AC Motors – Commonly used in industries and household appliances.

- DC Motors – Often found in battery-powered devices and industrial machinery.

- Servo Motors – Used in robotics and precision applications.

- Stepper Motors – Found in printers, CNC machines, and automated systems.

Common Issues in Electric Motors

- Overheating due to excessive load

- Bearing failures from lack of lubrication

- Electrical issues like short circuits

- Misalignment causing vibration and inefficiency

- Dirt accumulation leading to overheating

Regular Inspection and Cleaning

Dust and dirt can cause overheating and insulation breakdown. Regularly clean the motor and surrounding areas to avoid debris buildup. Use compressed air to remove dust from vents and cooling fans.

Lubrication Best Practices

Lubrication minimizes friction and prevents premature wear. Use manufacturer-recommended lubricants and apply them in proper intervals. Over-lubrication can be as harmful as under-lubrication, so follow the guidelines carefully.

Checking Electrical Connections

Loose or corroded electrical connections can cause voltage drops and overheating. Inspect and tighten terminals, ensuring all connections are secure and free from corrosion.

Balancing and Alignment

Misaligned motors cause excessive wear and vibration. Ensure shafts and couplings are properly aligned to avoid unnecessary stress on bearings and other components.

Monitoring Temperature and Overheating

Overheating reduces motor lifespan. Use infrared thermometers or temperature sensors to monitor heat levels. If a motor runs hotter than usual, investigate possible causes like overload, poor ventilation, or dirty components.

Vibration Analysis for Early Detection

Unusual vibrations often indicate mechanical issues. Use vibration analysis tools to detect imbalance, misalignment, or bearing wear early, preventing catastrophic failures.

Proper Storage of Electric Motors

If not in use, store electric motors in a dry, dust-free environment. Keep them away from moisture and extreme temperatures to prevent rust and insulation damage.

Preventive Maintenance Schedule

Create a checklist for routine inspections, lubrication, and electrical testing. Regular maintenance prevents costly repairs and extends the motor’s life.

Troubleshooting Guide

- Motor doesn’t start – Check power supply, fuses, and wiring.

- Excessive noise – Inspect bearings and alignment.

- Overheating – Clean vents and ensure proper ventilation.

- Reduced efficiency – Examine electrical connections and load conditions.

Conclusion

Maintaining electric motors is key to their long-lasting performance. Regular inspections, cleaning, lubrication, and monitoring can prevent major issues and ensure efficiency. A proactive maintenance approach saves time, money, and energy in the long run.

FAQs

- How often should I lubricate an electric motor?

It depends on the motor type and usage, but generally, lubrication is required every 3-6 months. - What are the signs of a failing electric motor?

Unusual noise, overheating, vibration, and reduced efficiency are common indicators. - Can I use any lubricant for my motor?

No, always use the lubricant specified by the manufacturer to avoid damage. - Why is my electric motor making a humming noise?

This could be due to electrical issues, misalignment, or bearing wear. - How can I prevent motor overheating?

Keep it clean, ensure proper ventilation, and avoid overloading the motor.